Revolutionizing Biomedical Devices: Measurement and Control Board used for Bench Bioreactor Solution

Measurement and Control Board used for Bench Bioreactor Solution

The biomedical industry is increasingly focusing on cutting-edge fields such as biopharmaceuticals and high-performance medical devices. In the biopharmaceutical sector, bioreactor technology is widely used in manufacturing raw materials of drugs, intermediates and finished products. Pharmaceutical intermediates and finished drugs such as penicillin, amino acids, polysaccharides, and enzymes can be mass-produced via advanced bioreactor technology that significantly reduces production costs and effectively decreases environmental impact.

1. Challenges with Traditional PLC Solutions

The typical solution for managing bioreactors involves using PLC systems to control components, monitor parameters of the reaction environment, and facilitate communication. However, the rapid advancements in processing techniques have highlighted the demands for bioreactor performance and several limitations of traditional PLC solutions:

• Complexity: Traditional PLCs, with their low computing power, require numerous modules to perform complex tasks, leading to bulky and cumbersome systems (Figure 1).

• Limited flexibility: Upgrading software and modifying system architecture in such complex systems with multiple PLC modules is challenging, hindering timely product updates and iterations.

• High maintenance costs: The extensive setup necessitates specialized on-site installation and maintenance, preventing direct delivery of fully assembled units.

Fig. 1 Complex PLC Systems Installed in Cabinet

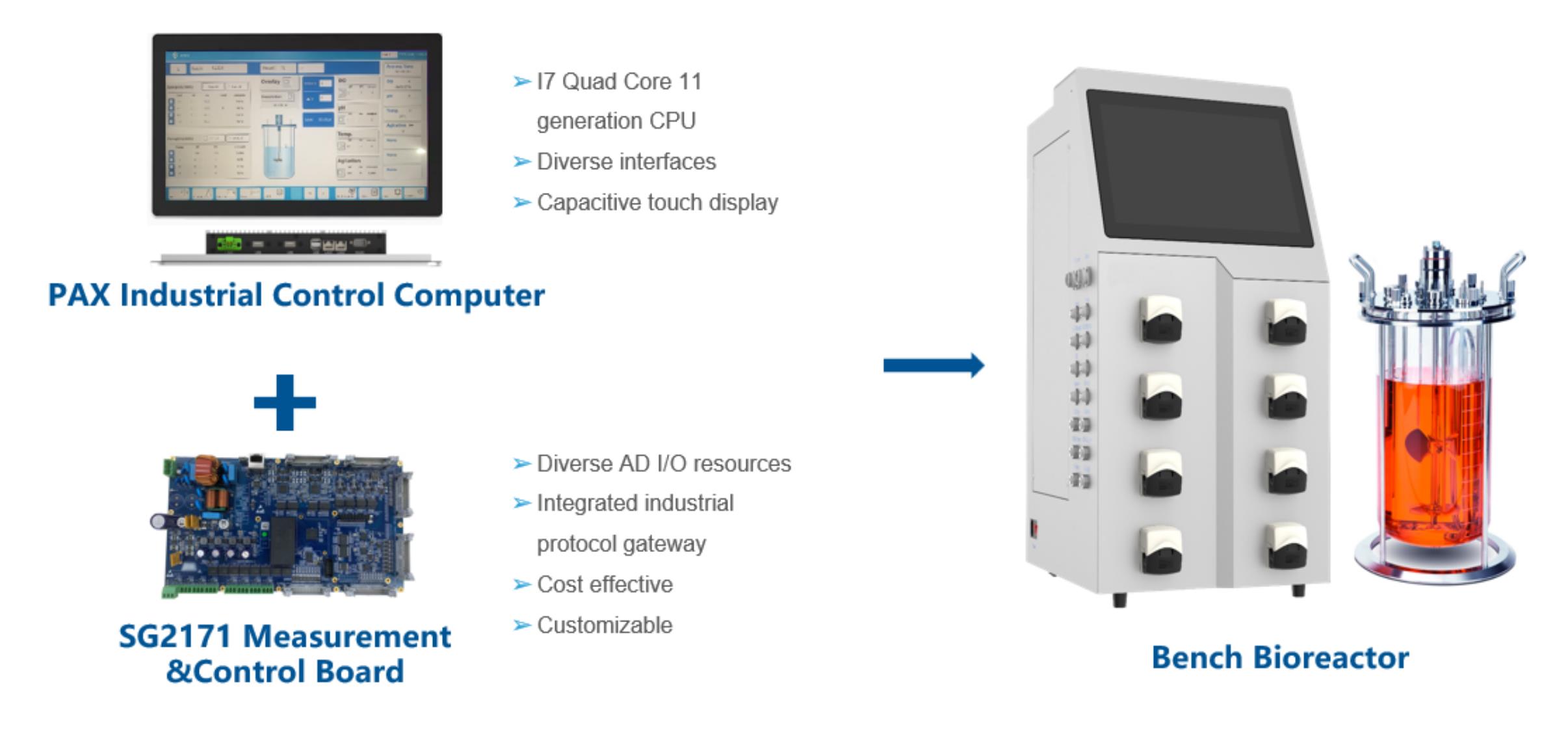

2. Smartgiant’s Bench Bioreactor Solution

To address the limitations of the current PLC systems, Smartgiant has developed an innovative solution, featuring an electronic system that seamlessly integrates a robust FPGA mainboard and an industrial computer. This design provides a powerful, compact control platform that enhances system stability and reliability of bioreactors. It supports data acquisition, management, monitoring, and communication, supports complex control software, and simplifies equipment control units.

Fig. 2 Schematic Diagram of Bench Bioreactor Solution

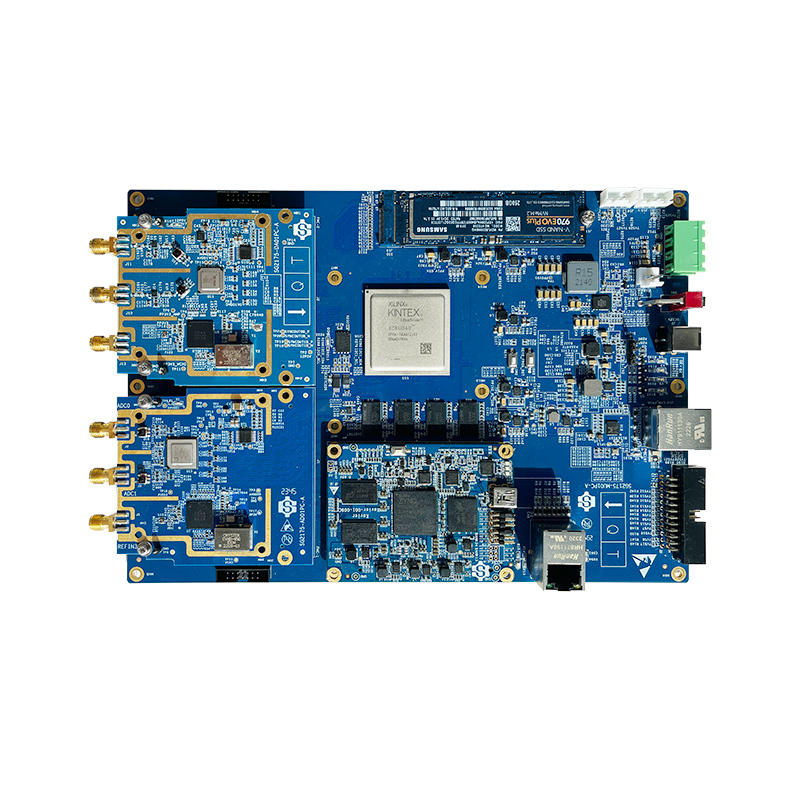

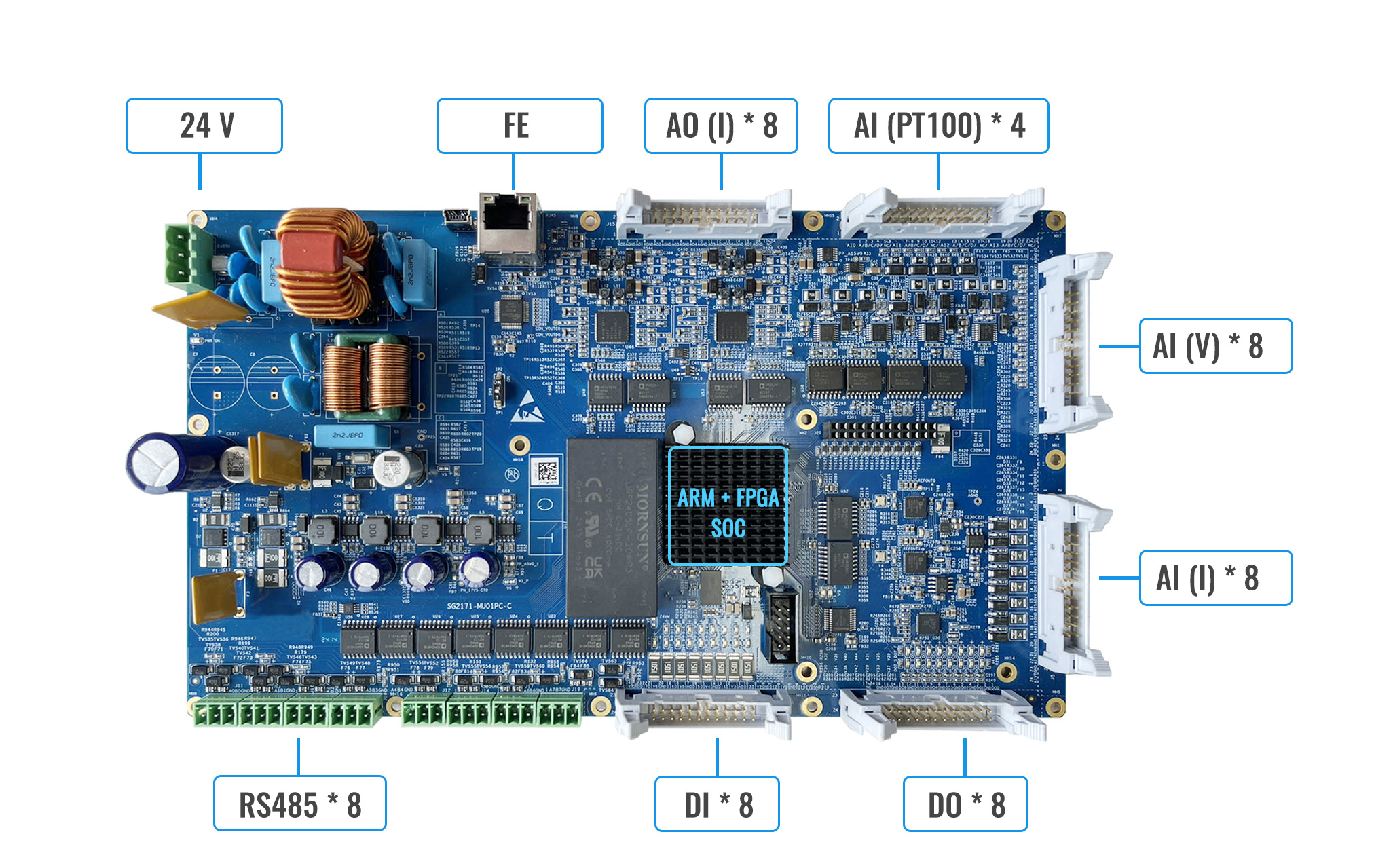

3. SG2171 Measurement and Control Board

The SG2171 Measurement and Control Board, is a motherboard designed for automation data acquisition, control, monitoring, and communication. Designed to meet industrial standards, this mainboard is engineered on a robust ARM+FPGA framework and is equipped with power capabilities for sensors, transmitters, and actuators. The system boasts high accuracy, stability, and reliability, supports the Modbus industrial protocol, and features fast response time and security. The SG2171 is primarily utilized across diverse sectors such as industrial automation, biomedical equipment, and environmental monitoring.

Fig. 3 Appearance of Measurement and Control Board

Key features:

- Industrial design: compliant with IEC standards

- A wide range of I/O resources (44 channels)

- Stable, reliable, and precise AFE signal conditioning

- 24-bit ADC high-resolution measurement performance

- A wide range of communication interfaces: 1*100M Ethernet upstream port (Modbus-TCP) and 8*RS485 downstream ports (Modbus-RTU)

- Supports channel isolation: digital-to-ground isolation

- Supports fault detection

- Customizable hardware interface, channel quantity and dimensions

Examples of applications scenarios:

4. PAX Industrial Computer

The PAX Industrial Computer is built on the 11th generation Intel I7 quad-core CPU, integrating a wide range of control interfaces and an industrial capacitive touch screen. This computer offers a wide range of software and hardware capabilities and features a compact structural design and high performance, making it ideal for uses in various sectors including biopharmaceuticals, industrial automation, new energy, and education and scientific research.

Fig. 5 PAX Industrial Computers

Key features:

- CPU+GPU architecture, Cortex-A72+/A53 Mail-T860

- Supports Android, Linux, and Windows operating systems

- Supports Wi-Fi 2.4 GHz/5 GHz

- No fan or small fan for heat dissipation

- Optional 4G network (integrated support for Mobile/China Unicom/Telecom)

- Offers RS485/RS232 interface

Application scenarios:

Smartgiant’s advanced bioreactor solutions not only address the limitations of traditional systems but also set new standards in technical support for the biomedical and biopharmaceuticals industries. Moreover, these solutions incorporate state-of-the-art technology that enhances the efficiency of cell culture processes. In addition, they provide real-time monitoring capabilities, which allow for precise adjustments during experiments.

Looking ahead, Smartgiant is committed to ongoing technological innovation and delivering high-quality products and services.

Related Aarticles:

From Data to Decision: Choosing the Perfect Data Acquisition System for Your Needs

Contact Us

Smartgiant Technology 1800 Wyatt Dr, Unit 3, Santa Clara, CA 95054.

Email: info@smartgiant.com

Contact Us

Smartgiant Technology 1800 Wyatt Dr, Unit 3, Santa Clara, CA 95054.

Email: info@smartgiant.com