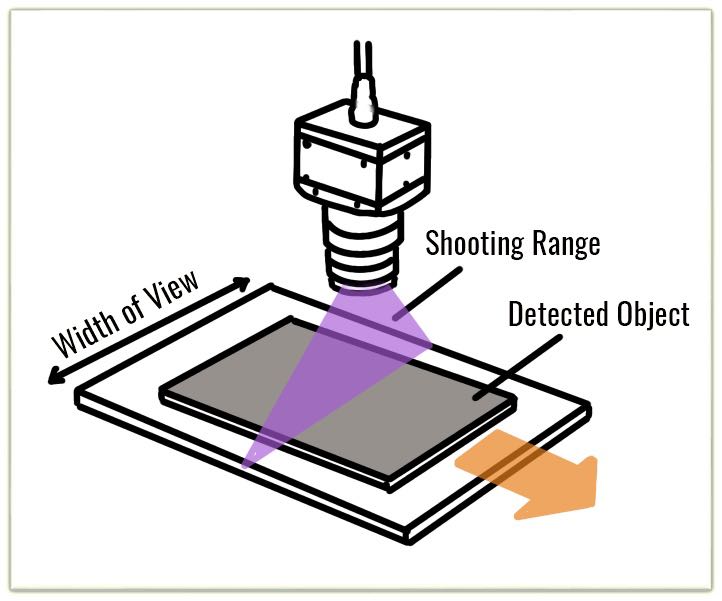

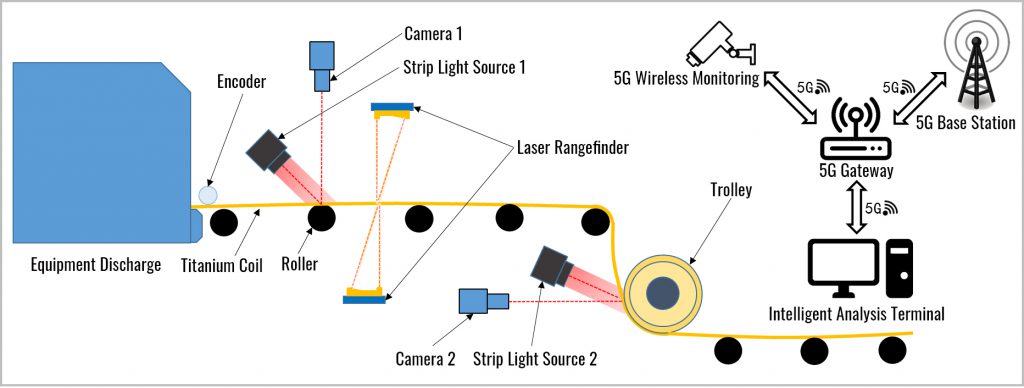

Schematic of the Principle

A line-scan camera adopts a line scan image sensor, which can achieve high-resolution, large field of view, and high-speed detection of ultra-high-level pixels. The typical application area is the detection of continuous materials, such as metals, plastic, paper, and fiber.

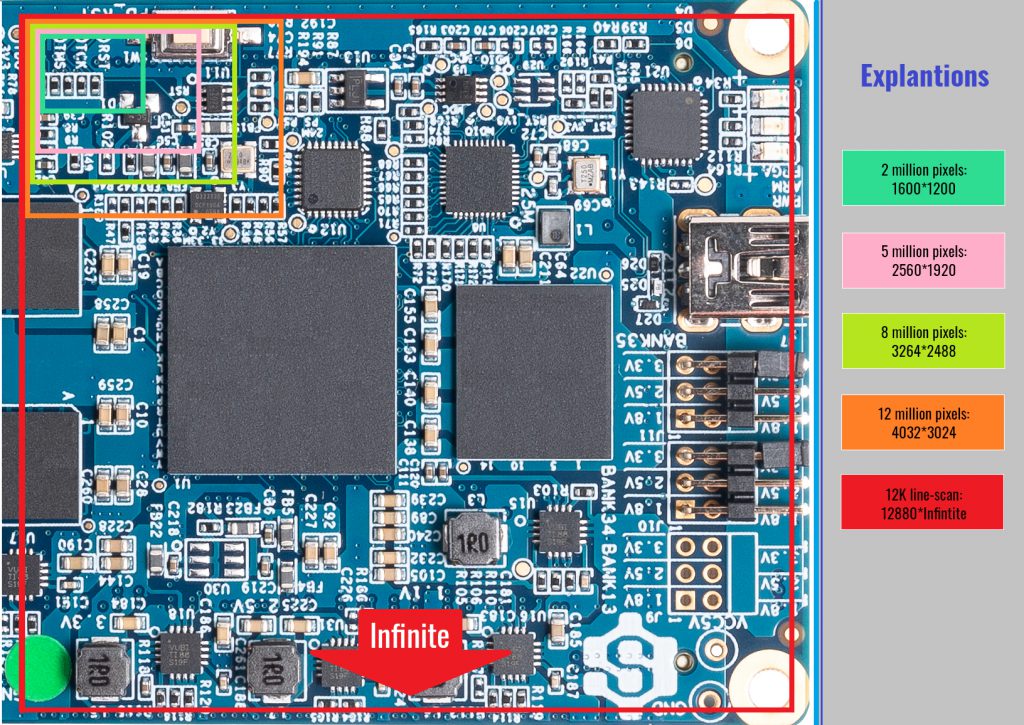

For example, a 12 K line-scan camera, when the number of line pixels is 12288 pixels, the maximum acquisition speed is 8 kHz, that is, an image of 12288 x 8000 size can be generated in 1 second (The resolution of the 5 M camera is 2592 x 1944).

System Features

1. A larger field of view can be provided for image acquisition

The use of black-and-white line-scan camera scanning imaging technology can simultaneously meet the requirements of high resolution and large field of view in detection, and obtain four times higher spatial resolution at a lower cost compared to other similar color cameras.

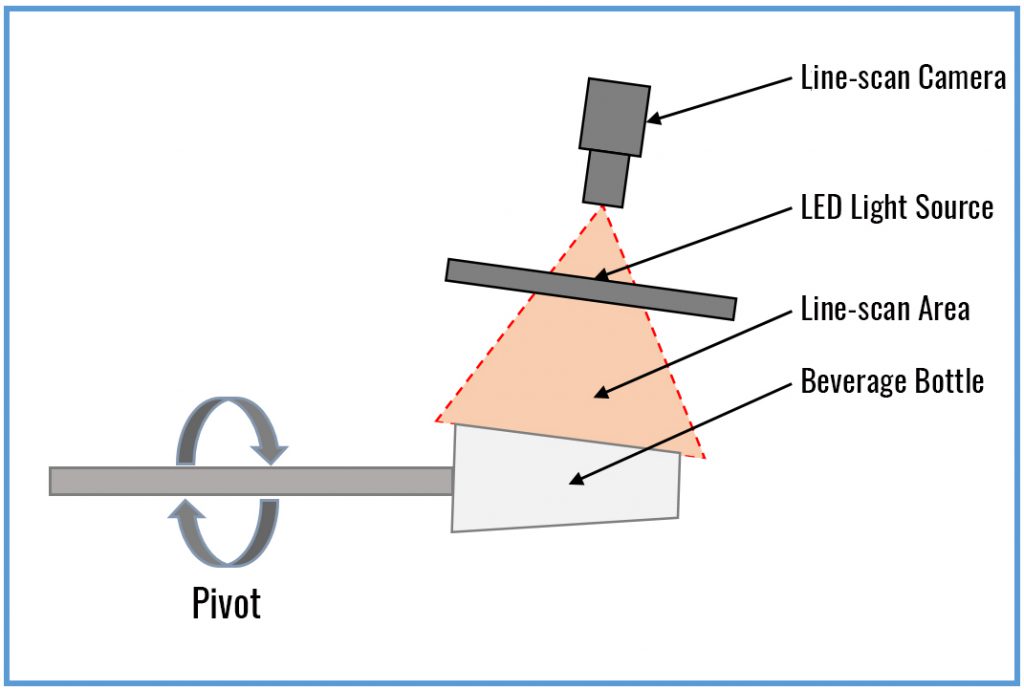

2. Consistent lighting makes surface detection possible

The system adopts linear scanning method to detect products, which can adaptively detect multiple types of curved surfaces. Conventional area-array scan cameras must rely on additional image correction algorithms, which not only increases the computational cost, but also causes greater deviations.

The system can perform defect detection for cylindrical, basiconical, and regular surfaces, such as Bluetooth speakers, lateral surfaces of beverage cups, mobile phone, and scratches on screens.

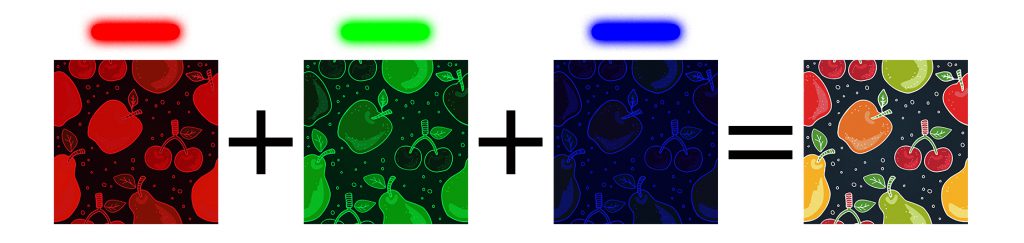

3. Enabling defect detection by multi-spectral technology

Black-and-white line-scan cameras use multi-spectral synthesis technology to obtain high-fidelity color images, which can offset color-related defect detection; it can also use special wavelengths to identify defects that are difficult to detect by the human eye, such as fingerprints, oil stains, and water stains.

Applications in Different Industries

- Beverage cup: rapid detection of appearance defects (e.g., printing, color accuracy, etc.)

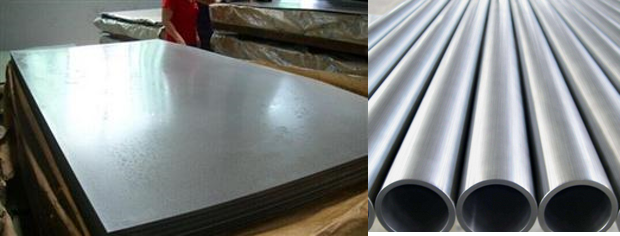

2. Rolled steel plates: check the flatness and dents on the surface of the steel plate; check the defect productions, such as steel pipe bending or fracture.

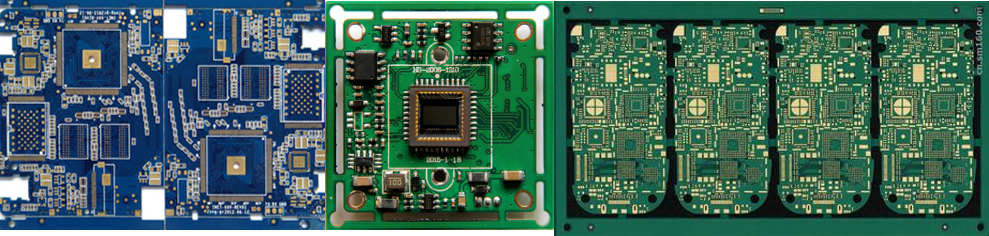

3. PCB:In contrast to the standard template, the system can detect various problems and defects of the actual PCB board.

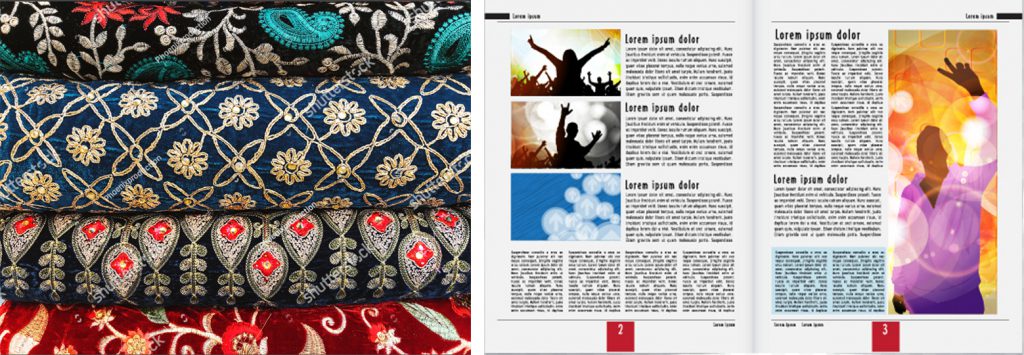

4. Printed products: the system can detect incorrect patterns and embroidery of oversized fabrics; erroneous words in books, poorly printed test papers, errors in newspapers, etc.

Application Scenarios

Notes:

1. Line-scan camera 1 and line-scan camera 2 detect the upper and lower surfaces of the titanium coil, respectively.

2. The encoder ensures that the camera takes pictures stably; the laser rangefinder measures the thickness.

3. The data is processed in the intelligent analysis terminal, and real-time monitoring is realized by the network.

Basic Optical Parameters Under Different Working Distances

| Serial Number | Working Distance (mm) | Horizontal Width of Field of View (mm) | Horizontal Magnification (β) | Optical Resolution (µm) |

| 1 | 200 | 245.76 | 0.175 | 40 |

| 2 | 250 | 307.20 | 0.140 | 50 |

| 3 | 300 | 368.64 | 0.117 | 60 |

| 4 | 350 | 430.08 | 0.100 | 70 |

| 5 | 400 | 491.52 | 0.088 | 80 |

| 6 | 450 | 552.96 | 0.078 | 90 |

| 7 | 500 | 614.40 | 0.070 | 100 |