Description

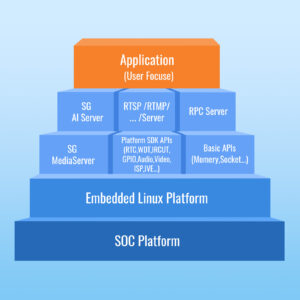

SmartGiant is developing a new generation of ACE vision platforms for industrial/commercial application scenarios — AI cameras (Argos) for image acquisition, edge computers (Cratos) for parallel computing, and vision software (Eos) for online inspection, configuration, and debugging. The working distances of AI cameras cover 18–1000 mm, enabling both high resolution and fast inspection. Autofocus, global shutter (shooting while moving), and PC-free decoding features are also available for different application scenarios.

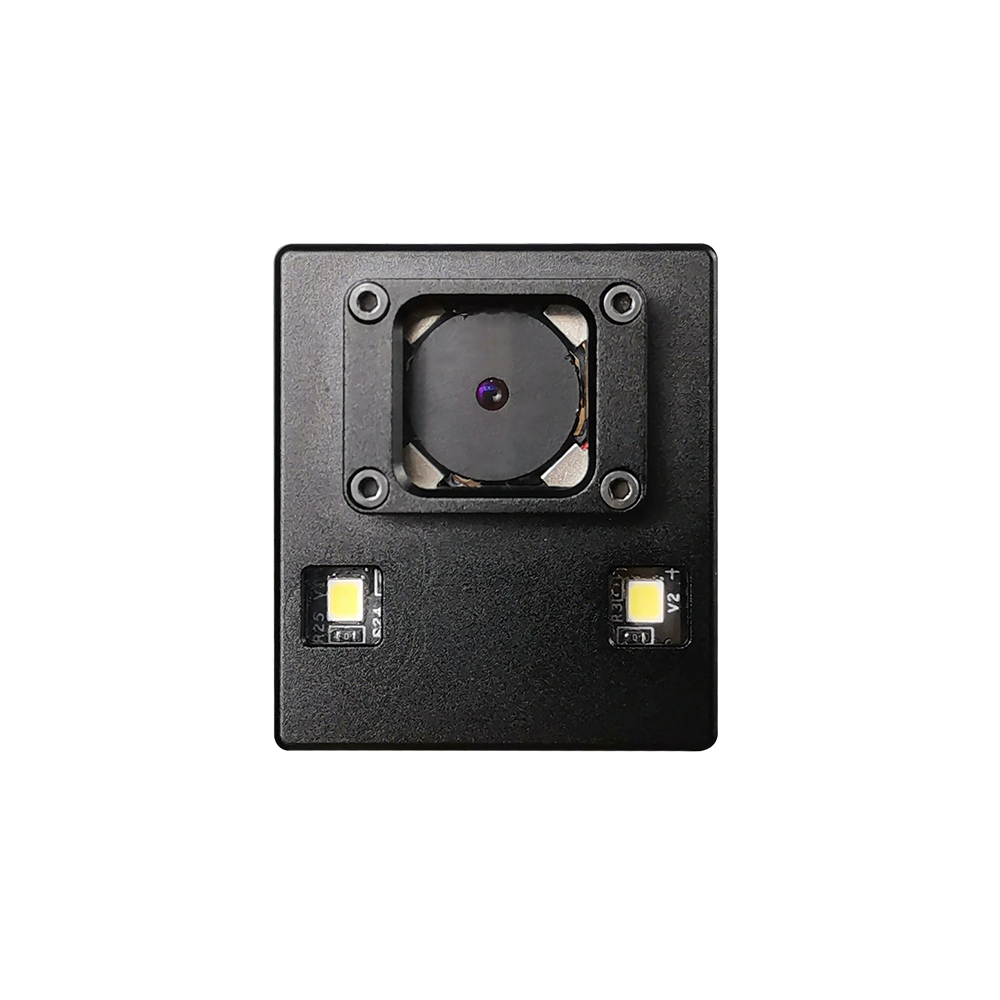

Argos AI macro industrial camera is mainly used in industrial fixed macro code scanning scenarios, scanning and reading barcodes, QR codes, and micro DM codes on the surface of various types of products in automated production line equipment. It can offer optimized algorithms to direct part marking (DPM) and laser carved code and automatically perform intelligent calibration for flawed images. It also supports options such as autofocus, global shutter (motion shooting), and on-chip decoding. Its configuration is simple and the size is small. There are two hardware configurations to meet different needs: the high resolution is good at multi-code recognition and the high frame rate is suitable for logistics recognition which can meet the code scanning needs during the production process of the electronic products. In addition to supporting industrial code scanning scenarios, Brontes can also be used in industrial visual recognition scenarios such as OCR, LED recognition, and AOI.

Specification table

| Model | Argos-101-001A (100-1000 mm) Argos-101-001B(50-100 mm) | ||

| Type | Fixed dynamic shooting | ||

| Dimensions | Length, Width, Height 40 mm × 35 mm × 46 mm | ||

| Reading specification | Bar code | Code39/93/128,

Code bar, ITF, EAN-8/13/125, UPC-A/E, Interleaved 2 of 5, Industrial 2 of 5 |

|

| QR code | QR,Micro QR,

Data Matrix (ECC200), Dot Code |

||

| Image receiving element | Type | CMOS, 1/2.8 inch, color, global shutter, 90fps | |

| Pixel number | 1280 (Horizontal) × 960 (Vertical) | ||

| Pixel size | 2μm×2μm | ||

| Illumination | Double white LED, single lamp 512 level dimming | ||

| Interface | Input control | Point | 1 |

| Input type | Optocoupler input | ||

| Minimum power-on voltage | 3.3 V | ||

| Minimum power-off current | 1 mA | ||

| Output control | Point | 1 | |

| Output type | Optocoupler output (Need self-connected pull-up resistor 10-100 kΩ) | ||

| Minimum pull-up voltage | 3.3 V | ||

| Max pull-up voltage | 26 V | ||

| Max power-off current | 100 mA | ||

| Ethernet | Communication standard | IEEE802.3az-2010

100Base-TX IEEE 802.3u 10Base-T IEEE 802.3 |

|

| Support agreement | TCP/IP | ||

| Serial communication | Communication standard | RS-232C | |

| Transfer speed | 9600, 19200, 38400, 57600, 115200 bps | ||

| USB | Communication standard | USB2.0 HIGH Speed | |

| Function (free drive) | UVC | ||

| Power | DC (5.5×2.1, Female) | 24 V±5%, 200 mA±10% | |

| Environmental tolerance | Shell protection level | IP54 | |

| Ambient temperature | 0-50°(No condensation) | ||

| Relative humidity | 35-85% (No condensation) | ||

| Shock resistance | 10 to 55 Hz, Double amplitude 1.5 mm, 2 hours each in X, Y, Z directions | ||

| Impact resistance | 500 m/s, 3 times each in 6 directions | ||

| Data interface | (Bus lead) 1×RS232, 1×USB2.0, 1×Ethernet, 2×I/O | ||

| Material | Main shell: aluminum alloy

Lens guard: optical glass Light goggles: optical glass |

||

| Weight | |||

Supported Software

| Name of software | Smart Vision Tool |

| Support OS | Windows 10 Professional or higher version 32 bit/64 bit

Windows 7 Professional or higher version 32 bit/64 bit |

| Operating environment | CPU 2.0Ghz, storage 1GB, hard disk 40G |